● Application

Magnetite is more easily selected than other minerals.

Magnetic separator, such as permanent magnetic separator, magnetic pulley and magnetic dewatering tank, was used before. In recent years, in view of the gradual refinement of the granularity of the magnetite and the improvement of iron concentrates in the ironmaking industry, the technological progress of magnetite beneficiation has been accelerated and remarkable results have been achieved, mainly including the application of new equipment such as fine sieve, magnetic separation column and weak magnetic separation - reverse flotation process, which has raised the grade of magnetite in China to 68.85%, silicon dioxide has dropped to 4%. Magnetite magnetic separation production line can be applied to a single magnetite ore with simple ore properties.

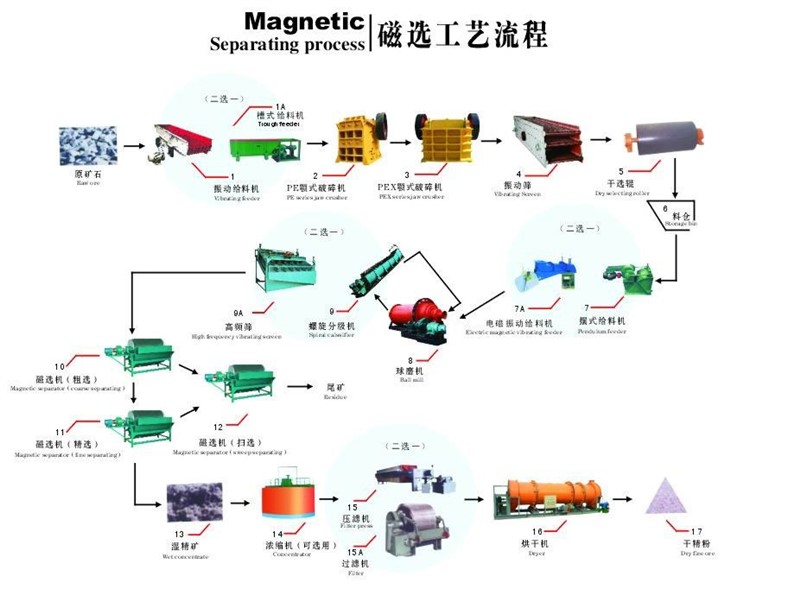

● Process introduction

1.crushing process: the iron ore is very hard, so the coarse jaw crusher is used for large jaw crusher, the crusher is added with the vibrating feeder before the jaw crusher, and the raw ore is sieved into two kinds of grain grade +75mm and -75mm, and the +75mm grain grade enters the jaw crusher for rough break, and the -75mm grain grade enters the cone crusher to break.

2. grinding process: as the hardness of the ore is large and the density of embedding is very fine, it is difficult to achieve the proper yield and the degree of monomer dissociation by ordinary grinding process. The two stage grinding process is adopted in this process, which not only reduces the ore mud and mill efficiency, but also improves the output, and achieves the required grinding fineness.

The selection of drum type magnetic separator: one magnetic separation machine is used for one stage of separation, and one magnetic separator is used for one stage of rough separation to achieve the requirement of 63 or more concentrates.

The de-magnetization process was added to the process of re-election to remove the magnetism of the mineral itself after magnetic separation, so as to avoid the generation of magnetic chains and affect the improvement of concentrate taste.