Principle overview:

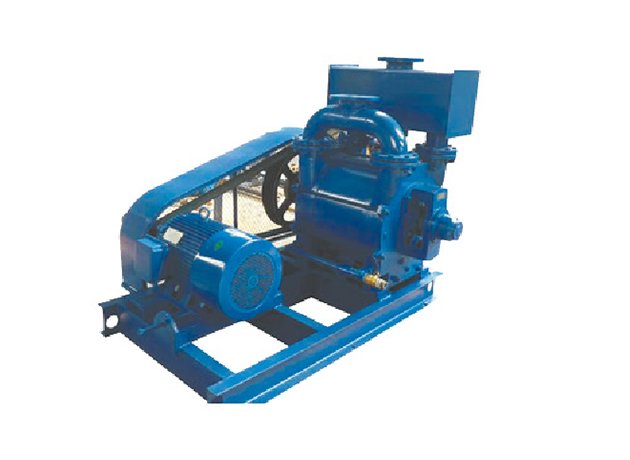

Water ring vacuum pump and compressor belong to volume changing design. As shown in the left , the rotor is Mounted inside the PUMP COVER, The rotation of the working fluid is forced to form a liquid ring which rotates in the same direction along the inner wall of the pump casing. Then an air Cavity is formed between the adjacent Blades, reel of impeller and the internal surface of the Circle of liquid. To the extent that the rotor rotates, the volume of Air Absorption area increases gradually, while Lowering the internal pressure of the same, so the Air will be absorbed into the pump; if the volume of Absorption area of the Air cavity in the pump reduces bit to be little, Internal pressure up, so that the Air will be discharged from the pump.

The Vacuum Pumps of water Circle and the Compressor 2be served extensively in various industrial sectors.The structure of the Vacuum Pumps of water Circle and the Compressor 2be provide that it is suitable for a variety of demanding, complex applications such as handling a large amount of water vapor and condensable gas medium, deal with highly flammable and explosive gas, deal with toxic and corrosive gas, and contain the fiber, tiny solid particles, or liquid entrainment and other conditions. To eliminate the air in the extruder, extrusion forming, packaging in Cans or bottles, Leather Drying process, Sterilizer, Birds, remove air to water, porous polystyrene foam etc.

In the Thermal Power Plant has five Features,such as: Condenser vacuum, drying device for flue gas desulfurization, ash Transportation,self priming of circulating pump and collection of hydrogen Cooling Generator.

In sectors such as the Petrochemical, Marine Chemical Industry, Petroleum, etc., has become a reliable guarantee of various devices of Process, such as: Crude distillation’s vacuum system at the top of toward , Vacuum crystallization,Seawater deoxidation, Vacuum system in polyester plant of chemical fiber plant and vacuum conveying of various materials

Other applications, such as:Vacuum system for paper industry,Vacuum filtration in coal washing plant,Vacuum drying in ore flotation,A variety of pressure swing adsorption (PSA) devices,Various devices in the pharmaceutical industry,bag type dust removal device.

2BE series water ring vacuum pump gray cast iron, stainless steel and other materials can be provided for users to choose.

Technical Parameters:

Model | Minimum Absolute pressure Absorption (hpa) | Pump Speed (r / min) | Maximum volume of Air (m 3 / min) | motor power (kW) | Transmission Type | Motor voltage(V) | Diameter of Absorption(mm) | Diameter of Discharge (mm) |

| 2BE1 202 | 33 | 790 | 9.5 | 18.5 | tape | 380 | 125 | 125 |

| 880 | 11 | 18.5 | tape | 380 | ||||

| 980 | 12 | 22 | Coupling | 380 | ||||

| 1100 | 14 | 30 | tape | 380 | ||||

| 1170 | 15 | 30 | tape | 380 | ||||

| 2BE1 203 | 33 | 790 | 14 | 30 | tape | 380 | 125 | 125 |

| 880 | 16 | 30 | tape | 380 | ||||

| 980 | 18 | 37 | Coupling | 380 | ||||

| 1100 | 20 | 45 | tape | 380 | ||||

| 1170 | 21 | 45 | tape | 380 | ||||

| 2BE1 252 | 33 | 558 | 20 | 30 | tape | 380 | 150 | 150 |

| 660 | 25 | 37 | tape | 380 | ||||

| 740 | 28 | 45 | Coupling | 380 | ||||

| 820 | 30 | 55 | tape | 380 | ||||

| 880 | 33 | 75 | tape | 380 | ||||

| 2BE1 253 | 33 | 560 | 28 | 45 | tape | 380 | 150 | 150 |

| 590 | 30 | 55 | tape | 380 | ||||

| 660 | 35 | 55 | tape | 380 | ||||

| 740 | 39 | 75 | Coupling | 380 | ||||

| 820 | 43 | 90 | tape | 380 | ||||

| 2BE1 303 | 33 | 466 | 43 | 55 | tape | 380 | 200 | 200 |

| 520 | 45 | 75 | tape | 380 | ||||

| 590 | 52 | 75 | Coupling | 380 | ||||

| 660 | 58 | 90 | tape | 380 | ||||

| 740 | 62 | 110 | Coupling | 380 | ||||

| 2BE1 353 | 33 | 390 | 55 | 75 | tape | 380 | 250 | 250 |

| 415 | 58 | 90 | tape | 380 | ||||

| 464 | 65 | 110 | tape | 380 | ||||

| 520 | 72 | 132 | Coupling | 380 | ||||

| 590 | 81 | 160 | tape | 380 | ||||

| 2BE3 400 | 160 | 300 | 68 | 75 | Reducer or tape | 380 | 300 | 300 |

| 323 | 80 | 90 | 380 | |||||

| 367 | 85 | 110 | 380 | |||||

| 393 | 92 | 110 | 380 | |||||

| 449 | 110 | 132 | 380 | |||||

| 2BE3 420 | 160 | 300 | 90 | 110 | Reducer or tape | 380 | 300 | 300 |

| 330 | 110 | 132 | 380 | |||||

| 360 | 120 | 132 | 380 | |||||

| 390 | 126 | 160 | 380 | |||||

| 430 | 134 | 185 | 380 | |||||

| 2BE3 500 | 160 | 242 | 125 | 160 | Reducer | 380 | 350 | 350 |

| 266 | 145 | 185 | 380 | |||||

| 294 | 165 | 200 | 380 | |||||

| 336 | 190 | 250 | 6KV | |||||

| 372 | 210 | 280 | 6KV | |||||

| 2BE3 520 | 160 | 236 | 150 | 185 | Reducer | 380 | 350 | 350 |

| 266 | 165 | 220 | 6KV | |||||

| 294 | 205 | 250 | 380 | |||||

| 336 | 235 | 280 | 380 | |||||

| 336 | 250 | 315 | 380 | |||||

| 2BE3 600 | 160 | 200 | 180 | 185 | Reducer | 380 | 400 | 400 |

| 236 | 210 | 250 | 6KV | |||||

| 266 | 240 | 280 | 6KV | |||||

| 294 | 260 | 315 | 6KV | |||||

| 336 | 285 | 350 | 6KV | |||||

| 2BE3 620 | 160 | 200 | 220 | 220 | Reducer | 6KV | 400 | 400 |

| 236 | 255 | 280 | 6KV | |||||

| 266 | 290 | 350 | 6KV | |||||

| 294 | 320 | 400 | 6KV | |||||

| 336 | 360 | 450 | 6KV | |||||

| 2BE3 670 | 160 | 170 | 305 | 315 | Reducer | 6KV | 500 | 500 |

| 200 | 370 | 450 | 6KV | |||||

| 236 | 440 | 560 | 6KV | |||||

| 266 | 500 | 630 | 6KV | |||||

| 291 | 560 | 800 | 6KV |