Principle overview:

Selection methods: equipment selection principle is based on slurry volume.When use this kind of equipment for mineral separation,the pulp concentration will cause certain impact on mineral processing index. If you need to get good dressing indexes, please reduce the pulp concentration.When the proportion of magnetic material is high, handling capacity is influenced by the total amount of magnetic medium trapping magnetic ore, so you should reduce the pulp concentration at this time. When selecting nonmetallic ore according to dry ore quantity , dry ore's handling capacity is half the standard quantity.

Selection instructions:

This product applies to -1.2 mm (-200 mesh 30~100%) fine red manganese ore(hematite, limonite, siderite etc.) , ilmenite and wolframites' wet sorting ,Separation of black and white tungsten and the separation of wolframite and cassiterite .It is also used for non metals impurity purification such as quartz, feldspar, nepheline and ore of kaolin.

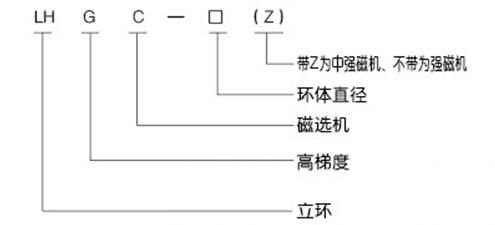

Model Description:

Technical Parameters:

Model | LHGC-5F | LHG-7F(Z) | LHGC-10F(Z) | LHGC-12F(Z) | LHGC-15F(Z) | LHGC-17F(Z) | LHGC-20F(Z) | LHGC-25F(Z) | LHGC-30F(Z) | LHGC-36F(Z) | ||

Rated background field strength (T) | 1.4(0.6)恒流连续可调 | |||||||||||

dielectric induced magnetic field (T) | 2.4(1.2)恒流连续可调 | |||||||||||

Rated excitation power (KW) | ≤20(6) | ≤30(8) | ≤40(10) | ≤50(12) | ≤60(15.5) | ≤72(23) | ≤85(29) | ≤98(37) | ≤110(48) | 102 | ||

Dry ore treatment capacity(t/h) | 0.03~0.125 | 0.1~0.5 | 4~7 | 10~18 | 20~30 | 30~50 | 50~80 | 100~150 | 150`250 | 250~400 | ||

The ability of pulp through(m) | 0.25~0.5 | 1~2 | 12.5~20 | 20~50 | 50~100 | 75~150 | 100~200 | 200~400 | 350~650 | 550~950 | ||

Magnetizing current (A) | 42 | 64 | 85 | 105 | 127 | 153 | 180 | 207 | 233 | 230 | ||

Feed Ore concentration(%) | 10~40 | |||||||||||

Feed size of ore | -1 | -1 | -1.2 | -1.2 | -1.2 | -1.2 | 1.2 | -1.2 | -1.2 | -1.2 | ||

Conversion speed (r/min) | 3 | |||||||||||

Conversion OD(mm) | φ500 | φ750 | φ1000 | φ1250 | φ1500 | φ1750 | φ2000 | φ2500 | φ3000 | φ3600 | ||

Conversion motor power (kw) | 0.18 | 0.75 | 1.1 | 1.5 | 3 | 4 | 5.5 | 11 | 18.5 | 30 | ||

Conversion motor power (kw) | 0.55 | 1.5 | 2.2 | 3 | 3 | 4 | 7.5 | 11 | 18.5 | 30 | ||

Pulse stroke (mm) | 0~30( Mechanical adjustable ) | |||||||||||

Pulse jig frequency (jig frequency s / min) | 0~300( frequency adjustable ) | |||||||||||

Excitation voltage (DCV) | 0~514(280)( With the change of current ) | |||||||||||

Discharge water pressure(Mpa) | 0.1~0.2 | 0.1~0.2 | 0.2~0.4 | 0.2~0.4 | 0.2~0.4 | 0.2~0.4 | 0.2~0.4 | 0.2~0.4 | 0.2~0.4 | 0.2~0.4 | ||

Discharge water consumption(m³/h) | 0.65~1.4 | 1.4~2.5 | 8~12 | 12~20 | 20~30 | 30~50 | 50~100 | 100~150 | 150~250 | 300~500 | ||

Host weight(t) | 4(1.5) | 8(3.5) | 15(7) | 24(11) | 34(20) | 45(28) | 60(39) | 125(83) | 165(135) | 308 | ||

Maximum component weight(t) | 0.5(0.25) | -1.1(0.5) | 3.3(2) | 5(3.5) | 7(4) | 15(9) | 20(13) | 32(18) | 38(19) | 35 | ||

Outline size length * width * height(mm) | 1800×1400×1320 | 2000×1360×1680 | 2700×2000×2400 | 3200×2340×2700 | 3600×2900×3200 | 3900×3300×3800 | 4200×3550×4200 | 5800×5000×5400 | 7600×6500×7200 | 8300×6750×7850 | ||

Cylinder sieve | - | YTS-810 | YTS-810 | |||||||||

| YTS-1210 | YTS-810 | |||||||||||

| YTS-1210 | YTS-810 | |||||||||||

| YTS-1210 | YTS-1415 | |||||||||||

| YTS-2019 | YTS-1415 | |||||||||||

| YTS-2019 | YTS-2019 | |||||||||||

| YTS-2529 | YTS-2529 | YTS-2529 | ||||||||||