Principle overview:

High frequency vibrating screen comprises a screen, a support frame, a vibrating motor or electromagnetic vibrator etc. The screen is made of high strength nylon fibers which benefits the reliable wear resistance. Electromagnetic vibrator uses the principle of half wave rectification which provide the strong vibration and even input to achieve the separation of coarse and fine materials The device can improve the concentrate grade up to three to five.Users would up to their own ore grade and processing capacity, specificity custom the size of specifications.

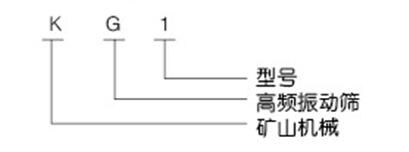

Model Description:

Technical Parameters:

Specifications | Power single phaseW | Distribution thyristor power supply 220v | Effective screen surface m2 | Screen mesh (hole) mm | Processing capacity t/h |

| KG-1 | 250 | 220V/10A | 4 | 0.1 | 3-5 |

| KG-2 | 250 | 220V/10A | 6 | 0.15 | 6-10 |

| KG-3 | 450 | 220V/10A | 8 | 0.2 | 12-16 |

| KG-4 | 650 | 220V/10A | 10 | 0.3 | 18-25 |

Main technical parameters of high frequency rotary screen

Specification model | Motor powerKw | Screen lengthm | Sieve cylinder diametermm | Screen mesh # | Processing capacityt/h |

| GZ-1 | 1.1 | 2 | φ800 | 100 | 5-8 |

| GZ-2 | 1.5 | 2 | φ1000 | 100 | 10-18 |

| GZ-3 | 2.2 | 3 | φ1200 | 100 | 16-20 |