Principle overview:

1. Modular non welded structure: Improper welding will change the performance of crusher, infecting the crusher's life, causing unnecessary repair while delaying production. The new crusher is divided into front and rear parts and separately cast, Let them connect with the side plate, the integral bearing seat and the pin bolt, making it easy to transport of crusher.

2. Integrated motor installation: When the crusher is out of the factory, the crusher has been installed the Electric motor bracket, the motor bracket and the crusher are integrated to reduce the installation space and the length of the V belt. Motor and crusher synchronous movement, increase the V belt life.

3. Finite element analysis: The crusher takes the professional mechanical design software to assist the design. From the part modeling to the mechanism analysis, from the dynamic analysis to the finite element analysis, the whole process is controlled effectively.

4.Improvement of crushing chamber model: Crushing chamber optimized design combine with a reasonable stroke, so that the crusher production is higher. No matter pebbles, mountain stone or ore, there are matching with the toothed plate.

5. The adjustment is more convenient and easy to realize automation: The new crusher takes wedge adjustment. Mechanical adjustment can make the crusher can be adjusted both in the work or in the shutdown, While after the hydraulic adjustment, the crusher can achieve automatic control, just press the button and you will be able to adjust and pre-tightened movable jaw .

6. Select parts: TPEV series crusher will provide a variety of parts, including feed hopper, flywheel belt pulley safety cover, automatic lubrication system, hydraulic adjustment system. These parts can greatly improve the efficiency of equipment, reduce production costs.

7. Structure Improvement: Takes advantage of the mechanism analysis to improve movable jaw stroke, achieving a greater stroke than ordinary crusher, so it will achieve higher productivity and efficiency.

8. Production processing: PEV Series crusher parts adopt the excellent alloy cast steel and thermal rolled alloy steel panel, so it will ensure long life and stability.

9. Increased bearing: the new crusher adopts 4 bearings of the same size, which is larger than the others crusher model with the same specification, and the service life is longer. The maintenance time of the movable jaw assembly is reduced, and the period of bearing replacement is prolonged.

10. Hydraulic Adjustment System Discharge port (Optional Equipment): Each crusher model can equip the hydraulic adjustment system. Through the cooperation of the hydraulic cylinder and the accumulator, will achieve to automatic adjust discharge port and pre-tightened movable jaw. Safe and reliable hydraulic system reduce the preparation before the equipment work, improve work efficiency, and ensure the safe operation of the host.

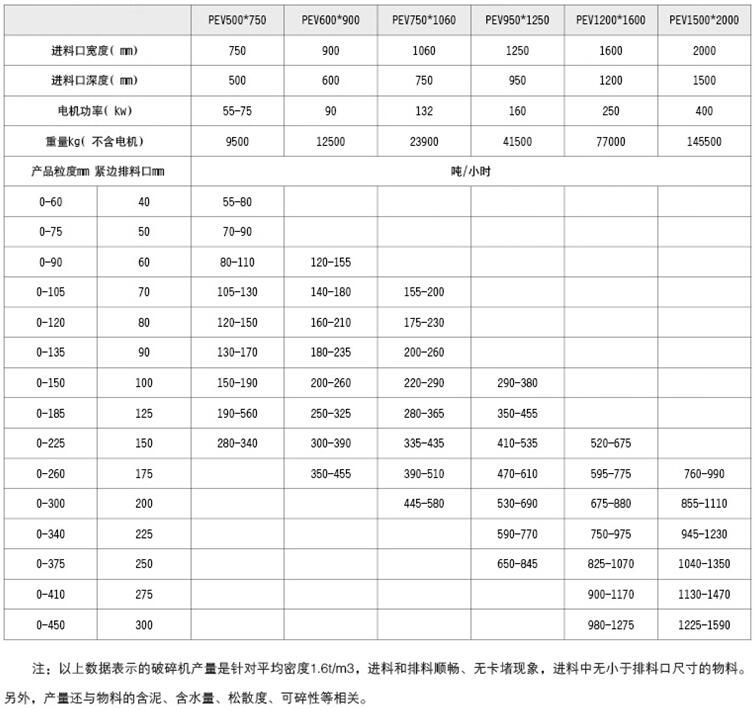

Technical Parameters: