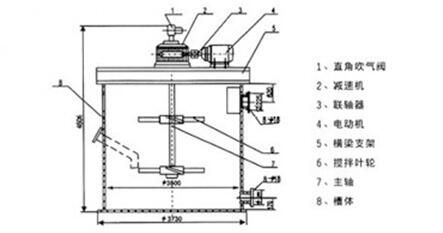

Principle overview:

During the double impeller drive and stirring,the slurry flow to bottom from top,diffusion through the surrounding damping plate ,by the mix air and slurry from shaft end to the top,comes out the suspension mixture liquid.

Selection instructions:

This series of stirred tank works for -200 mesh slurry fineness and accounted for more than 90%, the concentration smaller than 45% of the gold cyanide plant ,which used for mixing leaching and carbon adsorption.It also can be used for metallurgy, chemical industry and light industry department.

Model Description:

1. Ore flow smoothly, slurry mixing equality, low power consumption

2. The air passes through the hollow shaft into the slot, provide the equality air by stirring

3. Compact structure, convenient maintenance

4. Impeller lining glue, low cycle speed, long service life

5. This device is manufactured by the introduction of American technology;

6. Multiple points air charging system.

Technical Parameters:

Model | Tank specifications (Diameter * height) (mm) | Effective volume (m) | Speed (r / min) | Diameter of impeller (mm) | Motor type 2 | Motor power (kW) | Model of reductor | Tank weight (kg) | Total weight (kg) |

| SJ2.0x2.5 | 2000x2500 | 6 | 52 | 909 | Y100L1-4 | 2.2 | XLD2.2-4-29 | 1609 | 2144 |

| SJ2.5x2.5 | 2500x2500 | 9.82 | 43 | 935 | Y112M-4 | 4 | XLD4-5-35 | 2159 | 2729 |

| SJ2.5x3.15 | 2500x3150 | 13.14 | 52 | 935 | Y100L1-4 | 2.2 | XLD2.2-4-29 | 2398 | 3095 |

| SJ3.0x3.0 | 3000X3000 | 18 | 43 | 1130 | Y112M-4 | 4 | XLD4-5-35 | 3480 | 4583 |

| SJ3x3.15 | 3000x3150 | 18.93 | 3480 | 4160.6 | |||||

| SJ3x3.5 | 3000x3500 | 21 | 3200 | 4334.6 | |||||

| SJ3.15x3.55 | 3150x3550 | 24 | 1260 | 3433.5 | 4322.8 | ||||

| SJ3.5x3.5 | 3500x3500 | 30 | 52 | 1310 | Y1325-4 | 5.5 | XLD5.5-5-29 | 3480 | 5025 |

| SJ3.5x4 | 3500x4000 | 32.7 | 4230 | 5429 | |||||

| SJ3.55x4.0 | 3550x4000 | 33.6 | 43 | Y112M-4 | 4 | XLD4-5-35 | 4260 | 5025 | |

| SJ3.7x4.2 | 3700x4200 | 38.4 | 42 | XLD4-5-43 | 5266 | 6153 | |||

| SJ4.0x4.5 | 4000x4500 | 48 | 35 | 1750 | Y132M-4 | 7.5 | XLD7.5-7-43 | 6397 | 7569 |

| SJ4.0x6 | 4000x6000 | 70 | 33 | 1750 | Y160M-4 | 11 | GRF137-Y11-4P- | 7681 | 9200 |

| 44.65-M4 | |||||||||

| SJ4.5x5.0 | 4500x5000 | 71.57 | 35 | 1750 | Y132M-4 | 7.5 | XLD7.5-7-43 | 8614 | 10864 |

| SJ5.0x5.6 | 5000x5600 | 98 | 31 | 2046 | Y160M-4 | 11 | Xgranularidad1-8-47 | 8740 | 14291 |

| SJ5.5x6.0 | 5500x6000 | 112 | 2100 | 12467 | 18745 | ||||

| SJ6.5x7.0 | 6500x7000 | 195 | 21 | 2400 | Y180L-4 | 22 | GRF147-Y22- | 17890 | 25978 |

| 4P-70.87 | |||||||||

| SJ7.0x7.5 | 7000x7500 | 245.4 | 2400 | Y200L2-6 | 22 | XLD22-10-47 | 20505 | 29030 | |

| SJ7.5x8.0 | 7500x8000 | 268.6 | 23 | 2900 | Y200L2-6 | 22 | BLD7-43-22L | 22552 | 32796 |

| SJ8.0x8.5 | 8000x8500 | 319 | 18.5 | 3300 | Y250M-8 | 30 | TPS315-3F | 30559.5 | 42467.3 |

| SJ8.5x9.0 | 8500x9000 | 395 | 18.5 | 3300 | Y250M-8 | 30 | TPS315-3F | 34130 | 46623 |