Principle overview:

The feeder gives a bulk, granular, and powdery material from a storage reservoir or funnel to a receiving device in a uniform or continuous manner, It can be stepless adjustment of feeding quantity and realize the centralized control and automatic control of the production process.

It has the advantages of small size, light weight, convenient installation, no rotating parts, no lubrication, convenient maintenance, high work efficiency and less power consumption. Widely used in mining, metallurgy, coal, light industry, electricity, machinery, food and other industries. Regulating ore quantity method: adjust the current size. The amplitude of this equipment is small, high frequency, the viscosity or wet powdery material should not be used.

Selection instructions:

According to the scale of mineral processing and the operation system, the corresponding model of the ore feeder is provided by the production plant,

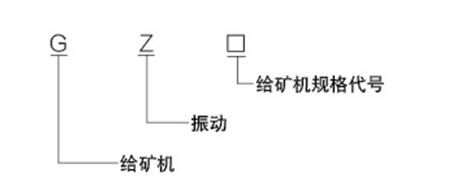

Model Description:

Technical Parameters:

| model | Production rate ≤T/h | Feed size ≤mm | Double amplitudeMm | Power~V | Power A | power kW | Matching control and model | weight | Overall dimension | ||||||||||

| level0° | -10° | Working current | Express current | ||||||||||||||||

| L1 | L2 | L3 | L4 | H1 | H2 | B1 | B2 | ||||||||||||

| Model | GZ0 | 5 | 7 | 50 | 1.75 | 220 | 1.34 | 1 | 0.06 | XK35 | 75 | 910 | 600 | 200 | 550 | 100 | 360 | 200 | 230 |

| GZ1 | 10 | 14 | 50 | 3 | 2.3 | 0.15 | 146 | 1175 | 800 | 310 | 660 | 120 | 450 | 300 | 388 | ||||

| GZ2 | 25 | 35 | 75 | 4.58 | 3.8 | 0.25 | 217 | 1325 | 900 | 311 | 790 | 150 | 520 | 400 | 496 | ||||

| GZ3 | 35 | 50 | 85 | 6.8 | 5.5 | 0.35 | 300 | 1460 | 1000 | 350 | 870 | 175 | 580 | 450 | 550 | ||||

| GZ4 | 50 | 70 | 100 | 8.4 | 7 | 0.45 | 412 | 1615 | 1100 | 413 | 960 | 200 | 645 | 500 | 620 | ||||

| GZ5 | 100 | 140 | 150 | 12.7 | 10.6 | 0.65 | 656 | 1815 | 1200 | 465 | 1050 | 250 | 765 | 700 | 850 | ||||