Principle overview:

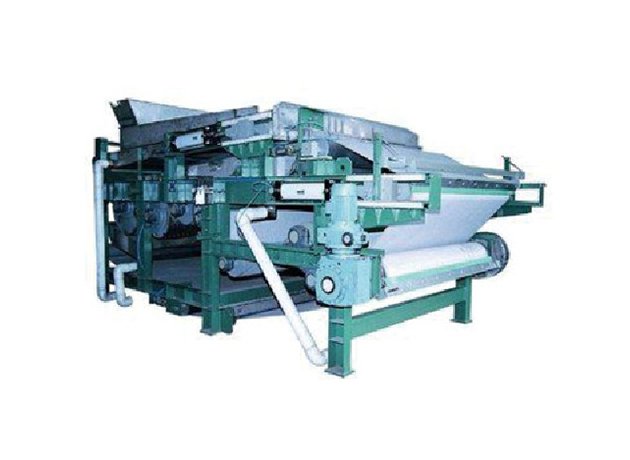

The belt filter Press ( Belt sludge dewatering machine) is used widely for urban sewage treatment, Textile printing,electroplate, Paper Industry, Leather, Food Processing, cleaning Coal, Mine, Petroleum, Chemical Industry, pharmaceutical and Ceramics etc, also suitable for the process of leaching liquid or solid - Liquid separation for the industry.

Selection instructions:

1. The use of ultra long filtration and strong pressure on the roll in the dehydration,featuring the high capacity and the rate of moisture content of filter cake will be 10% less than the general Machine;

2. The displacement Adjusting device and Tensioning of the belt Filter is Advanced and reliable, using air pressure to realize the automatic control;

3. height Mechanical Performance and strong capacity, and Super Strong anti-corrosion, the host is a guarantee for eight years and five years for the Bearings and Rubber Roller;

4. Can run continuously for 24 hours, Easy operation and Repair.

Technical Parameters:

Technical parameters | model | |||||

| DYQ 1000WP1 | DYQ 1500WP1 | DYQ 2000WP1 | DYQ 2500WP1 | DYQ 3000WP1 | ||

power(kW) | host | 1.5 | 2.2 | 3 | 4 | 5.5 |

set | 10 | 13 | 15 | 19 | 22 | |

Width of Belt(mm) | 1000 | 1500 | 2000 | 2500 | 3000 | |

capacity(m3/h) | 8~12 | 10~18 | 15~28 | 20~35 | 30~45 | |

| Dimension | Length (mm) | 5300 | 5300 | 5300 | 5300 | 5300 |

width (mm) | 1900 | 2400 | 2900 | 3400 | 3900 | |

height (mm) | 2000 | 2000 | 2000 | 2100 | 2100 | |

weight (KG) | 3000 | 4000 | 5500 | 7000 | 8500 | |